Understanding the Basics of Motor Starter

Motor starters are the essential electrical devices in the field of electrical systems, which deals with the management of electric motors. Application areas like industrial automation or just understanding how electric motors operate safely, motor starters play a crucial role. This blog will explain in detail what motor starters are, how they work, and why they are necessary for different uses.

What is a Motor Starter?

The motor starter is an electrical device for starting, stopping, and protecting electric motors. The primary function of a motor starter is to safely switch on the operation of an electric motor and provide overcurrent or voltage fluctuation protection to prevent its damage. A motor starter can be thought of as a “guardian” for an electric motor, operating in a smooth and efficient manner.

Key Functions of a Motor Starter

- Start and Stop Control: Motor starters provide a safe switching of an electric motor on or off.

- Overload Protection: They prevent motors from overheating due to excessive current draw.

- Short-Circuit Protection: Most motor starters include mechanisms for protection against short circuits that can badly damage pieces of equipment.

- Voltage Control: Some motor starters regulate the voltage applied to the motor at the time of start-up to reduce electrical stress on the systems.

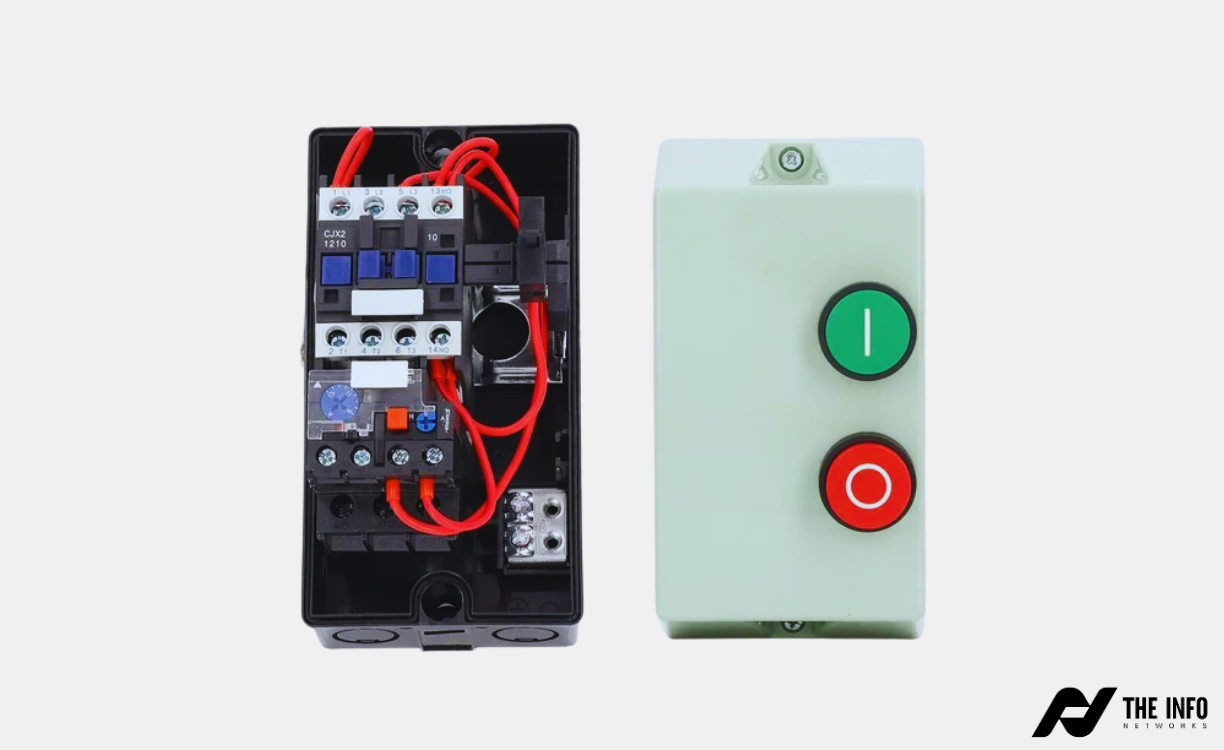

Basic Components of a Motor Starter

- Contactor: The heart of the switching device, the contactor controls the flow of power to the motor.

- Overload Relay: Monitors the current and disconnects the motor in case the current is exceeded to unsafe levels.

- Push Buttons or Switches: These provide the manual control for start and stop of the motor.

Different Types of Motor Starters

There are several types of motor starters which is commonly used, each suited to specific applications:

Direct-On-Line (DOL) Starter

Direct on line motor starters are Ideal for small motors, they handle the high initial current without damage.

How It Works:

- A DOL starter is the simplest type. It directly connects the motor to the full supply voltage.

- When you press the “start” button, an internal switch (called a contactor) closes, letting electricity flow straight to the motor.

- The motor immediately starts running at full speed but draws a high current for a short time.

Star-Delta Starter

A star delta motor starter is perfect for medium to large motors where reducing startup current is essential to prevent electrical system overloads.

How It Works:

- This starter uses two stages to start the motor.

- First Stage: The motor starts in a “star” configuration, which reduces the voltage to 1/√3 of the full supply. This keeps the initial current low.

- Second Stage: After the motor speeds up, it switches to a “delta” configuration, delivering full voltage for normal operation.

Soft Starter

Soft starters are best for machines sensitive to jerks or those where reduction of wear and tear is important.

How It Works:

- A soft starter gently ramps up the motor’s speed by gradually increasing the voltage supplied to it.

- This prevents sudden mechanical jerks and keeps the startup current low.

- Once the motor reaches full speed, the soft starter provides the normal operating voltage.

Magnetic Starter

Magnetic starters are common in factories where motors need to start and stop frequently with reliable protection.

How It Works:

- A magnetic starter uses an electromagnetic switch (a contactor) to control the motor.

- When you turn it on, the contactor closes, allowing current to flow to the motor.

- It includes overload protection; if the motor draws too much current or overheats, the magnetic starter shuts it down automatically.

How Does a Motor Starter Works?

- Press the “start” button, the contactor of the motor starter closes, allowing current to flow into the motor.

- This overload relay will continuously monitor the motor’s current to ensure it operates within safe limits.

- If the motor has drawn too much current, or a short circuit occurred, then the motor starter will trip to prevent damage.

- Pressing the “stop” button opens the contactor and cuts off power to the motor.

Why Motor Starters Are Important?

Motor starters are indispensable in both small-scale and large-scale electrical systems. Here’s why they matter:

- Equipment Protection: Electric motors are expensive components of any setup. A motor starter protects these motors from damage that may be caused by overloading, overheating, or sudden power surges.

- Improved Efficiency: With features like soft start and adjustable voltage control, motor starters make sure motors run efficiently to consume less energy at startup and during operation.

- Enhanced Safety: They prevent electrical fires or the failure of motors and hence make industrial and commercial operations safe.

- Motor Longevity: The motor starter reduces the stress put on motors while starting and maintains operation within specified parameters, thereby elongating the service life of an electric motor significantly.

When You Should Use a Motor Starter?

You should use motor starters in the following applications:

- When operating industrial motors that need good protection.

- For motors requiring controlled startup to prevent high inrush currents.

- In factories, workshops, and other locations where safety is crucial.

- When motors are involved in critical works where operations require efficiency and reliability.

Choosing The Right Motor Starter

Factors to consider when choosing a motor starter:

- Motor Type: The size and type of motor determine the type of starter needed.

- Application Requirements: Advanced starters, such as soft starters or auto-transformer starters, may be required for industrial applications.

- Voltage and Current Ratings: The starter must match the motor’s voltage and current ratings.

- Cost: Although DOL starters are less expensive, advanced soft starters offer improved savings in the long run.

Final Thoughts

Motor starters are essential in the operations of electric motors for efficiency and safety. Be it protecting motors from damaged conditions or increasing the efficiency of operations, their importance cannot be emphasized more. Whether using a simple DOL starter or an advanced soft starter, knowing how such a device works can help make an informed choice regarding which one to suit particular needs.

With motor starters, industries can rationalize and smooth their processes, minimize downtime, and allow for safety. Next time you see an electric motor, remember the crucial work of a motor starter that keeps it going.

FAQs About Motor Starters

Q1: What is a motor starter?

The motor starter is an electrical device for starting, stopping, and protection of electric motors.

Q2: How does a motor starter work?

It controls the flow of electricity towards the motor for smooth startup, continuous operation, and protection against overcurrent or short circuits.

Q3: Can motor starters reduce energy consumption?

Yes, advanced starters like soft starters save energy by regulating voltage applied to the motor during its start-up.

Q4: Do all electric motors require a motor starter?

Yes, motor starters are used in industrial and commercial applications due to the concern for safety, efficiency, and protection of motors.

Q5: How to select the right motor starter?

Please choose a motor starter based on the motor size, application it is used for, voltage/current ratings, and your budget.

Comments are closed